Tube Pack

Key Features

| High-Efficiency Tube Pack | : | Product Name Tube Pack / Lamella Tube Settler Material PVC / PP / ABS Shape Hexagonal / Chevron / Honeycomb Color White / Light Grey / Blue Tube Angle 60° Inclined Tube Diameter 50 mm – 80 mm Sheet Thickness 0.8 mm – 1.2 mm Length 1000 mm – 1500 mm Specific Gravity 0.9 – 1.0 Operating Temperature Up to 60°C Installation Type Modular, Easy to Assemble Chemical Resistance Excellent Service Life 10–15 Years Applications Water Treatment Plant, Wastewater Treatment, ETP, STP, Clarifiers, Sedimentation Tanks Advantages High settling efficiency, compact design, corrosion resistant, low maintenance, lightweight Origin Imported / Local Manufacturing Option |

| View More Info | ||

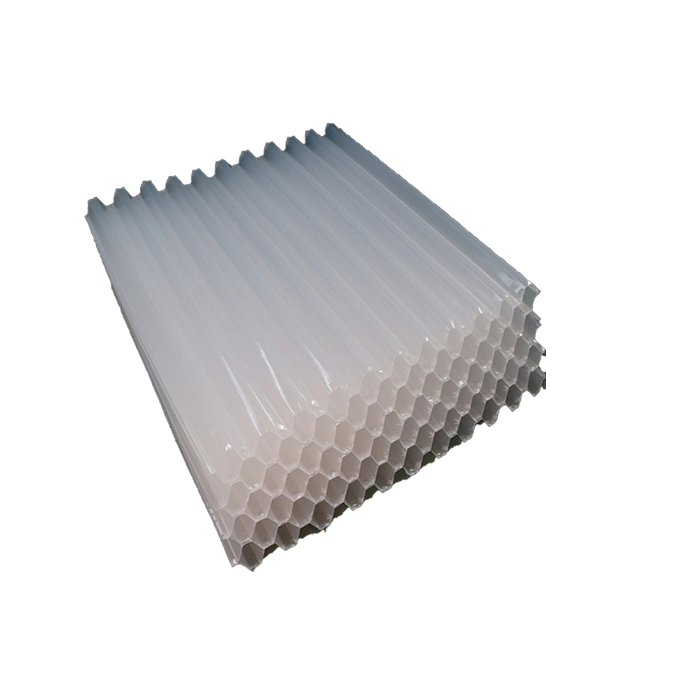

Tube Pack (Lamella Tube Settler)

A Tube Pack, also known as a Lamella Tube Settler Media or Tube Settler, is an advanced water clarification technology widely used in water and wastewater treatment plants. It is a modular system designed to improve the sedimentation process by increasing the effective settling area within clarifiers and sedimentation tanks. The structure of the tube pack is composed of several parallel tubes or channels that are usually inclined at a 60° angle. This configuration promotes faster and more efficient solid-liquid separation, allowing for compact system design and higher clarification rates.

Tube packs are typically made from high-quality, lightweight, and durable materials such as PVC (Polyvinyl Chloride), PP (Polypropylene), or ABS (Acrylonitrile Butadiene Styrene). These materials provide excellent chemical resistance, mechanical strength, and longevity even under harsh water treatment environments.

Working Principle

The working principle of a tube pack is based on lamella sedimentation technology. When water containing suspended solids enters the sedimentation tank, it flows upward through the inclined tubes of the tube settler. As the water travels through the tubes, the suspended particles start settling down due to gravity and reduced flow velocity inside each channel.

The settled sludge particles slide down along the inclined surfaces of the tubes and accumulate at the bottom of the tank, while the clarified water moves upward and exits through the outlet. The design significantly shortens the settling path, enhances particle settling velocity, and allows the treatment system to handle higher flow rates without compromising efficiency.

Key Features

Compact Design:

The tube pack’s honeycomb or hexagonal shape allows a large settling area within a small footprint, making it ideal for space-limited treatment plants.High Settling Efficiency:

The lamella principle increases the effective settling area by multiple times compared to conventional sedimentation basins, resulting in faster clarification.Durable and Lightweight Material:

Constructed from corrosion-resistant thermoplastics like PVC or PP, it is lightweight yet strong and long-lasting.Easy Installation and Maintenance:

Tube packs are modular and can be easily installed, replaced, or cleaned. They can be assembled on-site with minimal tools.Improved Hydraulic Flow:

The uniform geometry ensures consistent hydraulic distribution, reducing short-circuiting and turbulence in the tank.Chemical Resistance:

Suitable for use in both potable and industrial wastewater due to excellent resistance to acids, alkalis, and other chemicals.Long Service Life:

The UV-stabilized material ensures long operational life even in outdoor or exposed installations.

Applications

Tube packs are widely used in various water and wastewater treatment processes, including:

Municipal Water Treatment Plants:

For clarification, sedimentation, and turbidity reduction before filtration and disinfection.Wastewater Treatment Plants:

Enhancing primary and secondary clarification stages to remove suspended solids and improve effluent quality.Industrial Water Treatment:

In industries such as textiles, food processing, paper, steel, and chemicals, tube settlers are used for process water and effluent treatment.Sewage Treatment Plants (STPs):

Used to separate solid particles from domestic and municipal wastewater before biological treatment stages.Effluent Treatment Plants (ETPs):

Effective in clarifying wastewater from industries, ensuring compliance with discharge standards.Rainwater and Stormwater Clarification:

Useful in removing suspended particles and silt from rainwater collection systems.

Technical Advantages

Increased Settling Surface Area:

Tube packs can increase the effective settling area by up to 10–15 times compared to conventional clarifiers, enabling compact system designs.Reduced Retention Time:

Since sedimentation occurs quickly within inclined tubes, overall hydraulic retention time is reduced while maintaining high treatment efficiency.Enhanced Clarification Capacity:

Plants using tube settlers can handle higher flow rates without the need for additional large tanks or structures.Cost-Efficient Operation:

Lower capital cost due to reduced tank size and less civil construction work. Operating costs are also minimized due to low maintenance needs.Stable Performance:

Tube settlers perform efficiently under varying flow and load conditions, maintaining consistent effluent quality.

Material Specifications

Parameter | Typical Specification |

Material | PVC / PP / ABS |

Shape | Hexagonal / Chevron / Honeycomb |

Tube Angle | 60° |

Tube Diameter | 50 mm to 80 mm |

Sheet Thickness | 0.8 mm – 1.2 mm |

Length | 1000 mm – 1500 mm |

Color | White / Light Grey / Blue |

Installation Type | Modular, easy to assemble |

Specific Gravity | 0.9 – 1.0 |

Maximum Operating Temp. | 50–60°C |

Chemical Resistance | Excellent |

Service Life | 10–15 years (depending on use) |

Benefits

Space Saving: Up to 80% smaller footprint compared to conventional sedimentation tanks.

High Efficiency: Significantly increases sedimentation rate and particle removal efficiency.

Low Maintenance: Smooth surfaces prevent clogging and make cleaning simple.

Lightweight Construction: Easy to transport and install without heavy equipment.

Adaptable: Can be retrofitted into existing clarifiers to boost performance.

Sustainable Design: Reduces the need for energy-intensive filtration or mechanical clarification methods.

Installation and Maintenance

Installation is straightforward — the tube packs are pre-fabricated and can be mounted in the sedimentation tank using a support frame or stand. The inclination angle (typically 60°) ensures optimum settling and sludge removal. Maintenance involves periodic cleaning to remove any biological growth or debris buildup. For long-term performance, operators should ensure proper hydraulic flow and occasional inspection of physical integrity.

Cleaning can be done manually or with mild chemical washing, depending on the application and type of solids treated. Proper installation and routine maintenance can extend the system’s lifespan and maintain consistent performance.

Environmental and Operational Impact

The use of tube packs contributes to environmental sustainability by improving treatment efficiency and reducing land requirements for treatment facilities. They help produce cleaner effluent suitable for discharge or reuse, aligning with global water conservation goals. Moreover, since tube settlers require no electrical power to operate, they are energy-efficient and eco-friendly.

Conclusion

The Tube Pack (Lamella Tube Settler) is a modern, efficient, and cost-effective solution for improving sedimentation and clarification in water and wastewater treatment systems. Its design maximizes settling area, enhances efficiency, reduces footprint, and ensures long-term reliability with minimal maintenance. Whether in municipal, industrial, or environmental applications, tube settlers play a crucial role in achieving high-quality water treatment with sustainable performance.

Would you like me to also write SEO elements for this (like title, meta description, and keywords) for website use?

| High-Efficiency Tube Pack | Product Name Tube Pack / Lamella Tube Settler Material PVC / PP / ABS Shape Hexagonal / Chevron / Honeycomb Color White / Light Grey / Blue Tube Angle 60° Inclined Tube Diameter 50 mm – 80 mm Sheet Thickness 0.8 mm – 1.2 mm Length 1000 mm – 1500 mm Specific Gravity 0.9 – 1.0 Operating Temperature Up to 60°C Installation Type Modular, Easy to Assemble Chemical Resistance Excellent Service Life 10–15 Years Applications Water Treatment Plant, Wastewater Treatment, ETP, STP, Clarifiers, Sedimentation Tanks Advantages High settling efficiency, compact design, corrosion resistant, low maintenance, lightweight Origin Imported / Local Manufacturing Option |

|---|

(0)

Login To Leave Review

Related Products

EMI Details

T&C