Tube Diffuser

Key Features

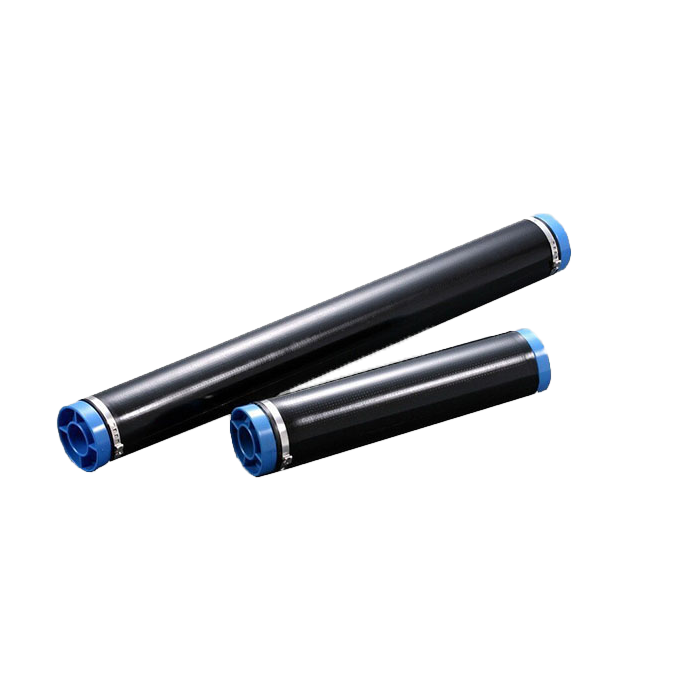

| High-Performance Tube Diffuser | : | Product Name Tube Diffuser Type Fine Bubble / Medium Bubble Membrane Material EPDM / Silicone / PTFE-Coated EPDM Body Material ABS / PVC Length 500 mm / 750 mm / 1000 mm Diameter 63 mm / 90 mm Pore Size 0.8 – 2.0 mm Bubble Size 1 – 3 mm Oxygen Transfer Efficiency (OTE) Up to 38% Air Flow Range 2 – 8 m³/hr per diffuser Operating Temperature Up to 80°C Connection Type Male Thread / Hose Connection / Clamp Type Color Black Body with Blue End Caps Installation Type Fixed or Retractable Aeration Systems Chemical Resistance Excellent Service Life 5 – 8 Years Applications STP, ETP, Aeration Tank, Biological Reactor, Fish Farming, Industrial Wastewater Treatment Advantages High oxygen transfer, low energy use, clog-resistant, durable design, easy maintenance Origin Imported / Local Manufacturing Available |

| View More Info | ||

High-Efficiency Tube Diffuser for Wastewater Aeration Systems

A Tube Diffuser is a highly efficient and durable aeration device designed for delivering fine or medium-sized air bubbles in wastewater treatment plants. It is a critical component in activated sludge systems, aeration tanks, and biological treatment processes, where oxygen transfer plays a key role in maintaining microbial activity and ensuring effective organic matter breakdown.

Tube diffusers are typically cylindrical in shape and are manufactured from robust materials such as EPDM (Ethylene Propylene Diene Monomer), Silicone, or PTFE-coated EPDM, combined with high-strength ABS or PVC end caps. Their design enables uniform air distribution, reduced back pressure, and high oxygen transfer efficiency — making them ideal for municipal and industrial wastewater applications.

With a combination of advanced materials, superior design, and precision perforation technology, the tube diffuser provides long-term, energy-efficient aeration performance in various water treatment systems.

Working Principle

The operation of a tube diffuser is based on the principle of fine bubble aeration. Compressed air is delivered through a pipe network into the diffuser, which is covered with a specially perforated membrane. When air passes through the diffuser’s small perforations, it is released into the water in the form of microbubbles.

These fine bubbles rise slowly through the water column, increasing the contact time and surface area for oxygen transfer. The dissolved oxygen supports the growth of aerobic microorganisms that degrade organic pollutants in the wastewater.

Due to the uniform bubble distribution and efficient diffusion mechanism, tube diffusers help maintain consistent oxygen levels throughout the tank, reducing energy consumption and improving the overall biological treatment process.

Key Features

High Oxygen Transfer Efficiency:

The fine bubbles provide a large surface area for oxygen transfer, enhancing aeration performance and reducing energy costs.Durable Construction:

Made from high-quality EPDM or Silicone membrane with reinforced ABS or PVC body, ensuring long operational life and chemical resistance.Uniform Air Distribution:

The precision perforation design ensures consistent airflow and prevents clogging or uneven air release.Low Energy Consumption:

Designed for low head loss and optimal bubble release, minimizing the energy needed for aeration.Anti-Clog and Anti-Fouling Design:

The self-cleaning membrane surface minimizes fouling, scaling, and biological growth, maintaining long-term efficiency.Flexible Installation:

Suitable for both fixed and retractable aeration systems; can be easily mounted on stainless steel, PVC, or HDPE pipelines.Corrosion and Chemical Resistance:

Resistant to acids, alkalis, and most industrial wastewater chemicals, ensuring reliable performance in harsh environments.Available in Various Sizes:

Common lengths include 500 mm, 750 mm, and 1000 mm, with customizable options to suit plant design.

Technical Specifications

Parameter | Specification |

Product Name | Tube Diffuser |

Type | Fine Bubble / Medium Bubble |

Membrane Material | EPDM / Silicone / PTFE Coated EPDM |

Body Material | ABS / PVC |

Length | 500 mm / 750 mm / 1000 mm |

Diameter | 63 mm / 90 mm |

Pore Size | 0.8 – 2.0 mm |

Bubble Size | 1 – 3 mm |

Oxygen Transfer Efficiency (OTE) | Up to 38% |

Air Flow Range | 2 – 8 m³/hr per diffuser |

Operating Temperature | Up to 80°C |

Connection Type | Male Thread / Hose Connection / Clamp Type |

Service Life | 5 – 8 years (depending on water quality) |

Applications

Tube diffusers are used extensively in various aeration and biological treatment processes, including:

Municipal Wastewater Treatment Plants (STP):

For biological oxidation, nitrification, and sludge stabilization.Industrial Wastewater Treatment Plants (ETP):

In industries such as food & beverage, textile, pharmaceuticals, paper mills, and chemical plants.Equalization and Aeration Tanks:

To maintain uniform mixing and prevent sludge settling at the bottom.Fish Farming and Aquaculture:

For oxygen enrichment in aquaculture ponds and tanks.Ozonation Systems:

For diffusing ozone or air uniformly in disinfection processes.Sewage and Effluent Aeration:

For maintaining aerobic conditions in biological reactors.

Advantages

Energy Efficiency:

Produces fine bubbles that enhance oxygen transfer efficiency, reducing blower energy costs.Low Maintenance Requirement:

Self-cleaning membrane minimizes fouling, reducing the need for frequent cleaning.Uniform Air Flow:

Provides even air distribution across the entire aeration basin.Easy Installation:

Lightweight, compact, and compatible with standard fittings for quick installation or replacement.Long Service Life:

Constructed with high-quality materials ensuring durability and consistent performance.Flexible Operation:

Can be used with different types of blowers and compressors for both continuous and intermittent aeration systems.Cost-Effective Solution:

Offers high performance at a relatively low operational cost, providing great value for wastewater plants.

Performance Benefits

Increases dissolved oxygen (DO) levels effectively.

Enhances biological treatment efficiency.

Reduces sludge volume and odor problems.

Minimizes system downtime with low clogging risk.

Improves effluent quality, meeting environmental discharge standards.

Adapts to various tank shapes and sizes.

Installation and Maintenance

Tube diffusers can be installed horizontally or vertically, depending on the tank design and air distribution system. The diffusers are typically mounted on lateral air distribution pipes that form part of the aeration grid.

For optimal performance, ensure:

Even air distribution across all diffusers.

Periodic inspection of membranes for scaling or damage.

Use of clean and dry compressed air to prevent clogging.

Regular monitoring of dissolved oxygen (DO) levels to maintain efficiency.

When properly maintained, tube diffusers can operate efficiently for 5 to 8 years or even longer, depending on water quality and operational conditions.

Material Options and Selection Guide

Membrane Type | Features | Best For |

EPDM | Economical, good chemical resistance | General wastewater applications |

Silicone | Excellent heat and chemical resistance | Industrial wastewater or hot effluent |

PTFE-coated EPDM | Anti-fouling, long service life | Harsh industrial and high-solid applications |

Selecting the right membrane depends on the type of wastewater, operating temperature, and oxygen demand of the system.

Environmental and Operational Impact

Using tube diffusers in wastewater treatment contributes to energy conservation, improved effluent quality, and sustainable operations. Fine bubble aeration is recognized as one of the most energy-efficient oxygen transfer technologies in modern treatment plants, helping facilities meet environmental standards with reduced carbon footprint.

Additionally, the low-noise operation and minimal maintenance requirements make tube diffusers a preferred choice for both new installations and retrofits.

Conclusion

The Tube Diffuser is an advanced, energy-efficient, and durable aeration solution designed to enhance oxygen transfer and biological treatment in wastewater systems. With its robust construction, uniform air distribution, and long service life, it stands out as a reliable and cost-effective option for both municipal and industrial applications.

By ensuring optimal oxygen levels, tube diffusers help achieve superior effluent quality, reduced operational costs, and sustainable water management — making them an indispensable component in modern wastewater treatment systems.

| High-Performance Tube Diffuser | Product Name Tube Diffuser Type Fine Bubble / Medium Bubble Membrane Material EPDM / Silicone / PTFE-Coated EPDM Body Material ABS / PVC Length 500 mm / 750 mm / 1000 mm Diameter 63 mm / 90 mm Pore Size 0.8 – 2.0 mm Bubble Size 1 – 3 mm Oxygen Transfer Efficiency (OTE) Up to 38% Air Flow Range 2 – 8 m³/hr per diffuser Operating Temperature Up to 80°C Connection Type Male Thread / Hose Connection / Clamp Type Color Black Body with Blue End Caps Installation Type Fixed or Retractable Aeration Systems Chemical Resistance Excellent Service Life 5 – 8 Years Applications STP, ETP, Aeration Tank, Biological Reactor, Fish Farming, Industrial Wastewater Treatment Advantages High oxygen transfer, low energy use, clog-resistant, durable design, easy maintenance Origin Imported / Local Manufacturing Available |

|---|

(0)

Login To Leave Review

Related Products

EMI Details

T&C